The Saxdor Shipyard’s four production facilities, located in Elk and Olecko, Poland, have a combined area of almost 21,000 square meters.

Strategically located in one of Europe’s key boat-building clusters, they enable efficient production and distribution, thanks to modern infrastructure and skilled workforce.

The newly opened 4,000 square meter shipyard in Larsmo, Finland, began operations in August 2024. The Larsmo region, with its long history of boatbuilding for several world-class boat brands, is dedicated to the production of Saxdor boats 40 feet and up, significantly increasing our production capacity and enhancing our ability to meet the growing demand for our boats.

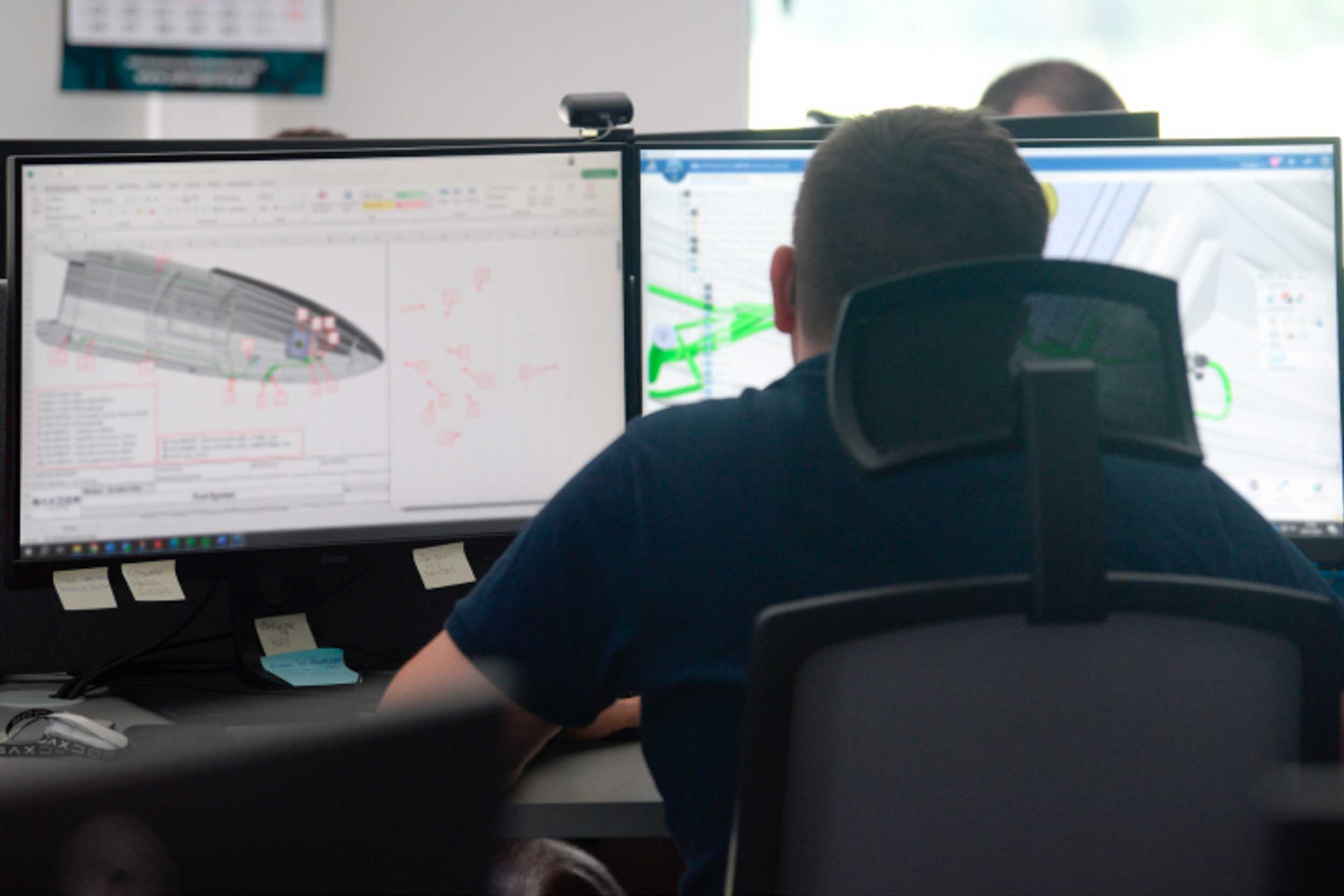

OPERATIONS

CENTER

At the core of the shipyard, our operations center integrates design, engineering, production planning, sourcing, finance and administrative functions. Teams work collaboratively to ensure seamless workflows, precise coordination, and adherence to high efficiency standards, essential for the shipyard's success.

HIGH-TECH

HULLS

Our advanced vacuum infusion process ensures that all Saxdor boats feature lightweight, high-strength hulls. This method improves structural integrity, optimizes performance, and enhances build quality while reducing styrene emissions, creating a healthier work environment for our team.

FINE JOINERY

Our woodwork division is essential in shaping the wooden details of Saxdor boats. Skilled craftsmen design and hand-finish each element, combining traditional methods with modern techniques. This approach ensures custom, high-quality interiors that enhance both aesthetics and the overall onboard experience.

TRUSTED

PARTNERS

We work closely with a network of trusted subcontracting partners who specialize in key components of boat production. These collaborations ensure that each element of our vessels aligns with Saxdor’s high-quality standards and technological demands, contributing to the excellence of our final products.

FINAL

ASSEMBLY

Our assembly line is where skilled technicians bring together each component with precision and care. Every boat is assembled, ensuring flawless integration of all parts. This thorough process guarantees consistent quality, ensuring each vessel upholds Saxdor’s high-performance and durability standards.

INTUITIVE

DASHBOARD

Saxdor dashboards are crafted with expertise, integrating advanced technology and ergonomic design to maximize functionality. Each dashboard is built with intuitive navigation and control systems and high-quality displays, offering a user-friendly interface that enhances onboard operations.

IN-HOUSE

TESTING

Our in-house testing pool offers a controlled environment for evaluation of each motorboat. This ensures that every vessel meets performance standards and safety requirements before leaving the shipyard. The testing process guarantees seaworthiness and readiness to exceed the expectations of our customers.

QUALITY

CONTROL

Quality control is integrated in every stage of production, from pre-inspections to in-process and end-stage inspections. We rely on precise measurement tools, statistical analysis, and specialized software to monitor and maintain consistency throughout the entire manufacturing process.

Saxdor Family Day 2024, Elk,Poland

OUR TEAM

At Saxdor, our people are the foundation of our success. Every individual, from engineers to craftsmen, plays a crucial role in shaping the quality of our boats. Together, we work as one team with a shared goal: delivering the best possible experience for our customers.